The manufacture of silk is certainly the most complex (and by far the most expensive) of all textile fibers.

First of all it is necessary to have a plantation of mulberry trees whose leaves are the only source of food for the silkworm.

The silkworm is carefully cultivated from the egg stage through the completion of the cocoon.

The silk filament is produced by the silkworm's two pairs of glands and it consists of two very fine single filaments of fibroin which are cemented together by a sticky substance called sericin.

Each cocoon is formed by a very long filament (up to 1100 yards long) whose length is almost always uninterrupted.

The unwinding and reeling into hank form are complex and very delicate processes which require an extensive use of labor.

The silk filament is produced by the silkworm's two pairs of glands and it consists of two very fine single filaments of fibroin which are cemented together by a sticky substance called sericin.

Each cocoon is formed by a very long filament (up to 1100 yards long) whose length is almost always uninterrupted.

The unwinding and reeling into hank form are complex and very delicate processes which require an extensive use of labor.

During the various phases water soaking at various temperatures and even steam is employed.

All of these processes induce a weight loss of at least 60% of the cocoon's initial weight.

The next step is a process called throwing whose purpose is to twist and unite together some filaments (from 3 to 20). In this way a rather sturdy yarn is obtained for the next working phases.

It should be considered that the single silk strand is extremely fine

During the various phases water soaking at various temperatures and even steam is employed.

All of these processes induce a weight loss of at least 60% of the cocoon's initial weight.

The next step is a process called throwing whose purpose is to twist and unite together some filaments (from 3 to 20). In this way a rather sturdy yarn is obtained for the next working phases.

It should be considered that the single silk strand is extremely fine

|

(1300 miles weigh 1lb.) and its cross-section is 8-10 microns, which is much finer than the best wool and cashmere.

At this point the silk yarn is still very coarse because it contains sericin , a sticky and rough substance, whose purpose is to hold together the two original filaments.

The characteristic hand of the best fabrics is obtained through the elimination of sericin, which is usually done in a natural and delicate process (hot soap and water) called degumming. The weight is further reduced by about 20%.

Natural silk is ivory colored. It is whitened or colored by soaking it for several hours in stainless steel bins containing warm liquid in the desired color.

At this point the silk yarn is ready for weaving which is an extremely complex process.

Natural silk is ivory colored. It is whitened or colored by soaking it for several hours in stainless steel bins containing warm liquid in the desired color.

At this point the silk yarn is ready for weaving which is an extremely complex process.

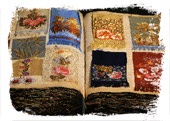

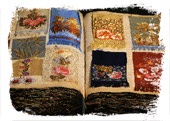

There are two main types of weaving for silk, "heddle", a plain weave which is normally used to weave all other fabrics and "jacquard" weave.

There are two main types of weaving for silk, "heddle", a plain weave which is normally used to weave all other fabrics and "jacquard" weave.

|

Through the constant and independent control of each warp thread (which can reach up to 15/18000), it

is possible to obtain designed fabrics such as damask, lampas, brocade and even tapestry in various colors.

This is the most complex and sophisticated weaving of all times.

It is interesting to note that the jacquard mechanism (invented by Joseph-Marie Jacquard in 1801) is considered the forerunner of the computer.

Certain types of silk fabrics undergo the characteristic process of printing.

This is done by laying out ink colors in successive stages (up to 20-25) and using the proper clichˇs thus creating exceptionally rich and varying patterns.

The "moirè" process involves a very light and delicate moving of some weft threads by means of perfect stainless steel cylinders. The threads which have been moved reflect light in a different way from the others with surprising optic effects. The fabrics obtained in this way are called "moirè".

This is done by laying out ink colors in successive stages (up to 20-25) and using the proper clichˇs thus creating exceptionally rich and varying patterns.

The "moirè" process involves a very light and delicate moving of some weft threads by means of perfect stainless steel cylinders. The threads which have been moved reflect light in a different way from the others with surprising optic effects. The fabrics obtained in this way are called "moirè".

Ties are produced either with jacquard or printed fabrics applied on plain cloth and the most luxurious are on jacquard fabrics which already have a rich background pattern. (see Tie-manufacturing)

Ties are produced either with jacquard or printed fabrics applied on plain cloth and the most luxurious are on jacquard fabrics which already have a rich background pattern. (see Tie-manufacturing)

|

The silk filament is produced by the silkworm's two pairs of glands and it consists of two very fine single filaments of fibroin which are cemented together by a sticky substance called sericin.

Each cocoon is formed by a very long filament (up to 1100 yards long) whose length is almost always uninterrupted.

The unwinding and reeling into hank form are complex and very delicate processes which require an extensive use of labor.

The silk filament is produced by the silkworm's two pairs of glands and it consists of two very fine single filaments of fibroin which are cemented together by a sticky substance called sericin.

Each cocoon is formed by a very long filament (up to 1100 yards long) whose length is almost always uninterrupted.

The unwinding and reeling into hank form are complex and very delicate processes which require an extensive use of labor.

During the various phases water soaking at various temperatures and even steam is employed.

All of these processes induce a weight loss of at least 60% of the cocoon's initial weight.

The next step is a process called throwing whose purpose is to twist and unite together some filaments (from 3 to 20). In this way a rather sturdy yarn is obtained for the next working phases.

It should be considered that the single silk strand is extremely fine

During the various phases water soaking at various temperatures and even steam is employed.

All of these processes induce a weight loss of at least 60% of the cocoon's initial weight.

The next step is a process called throwing whose purpose is to twist and unite together some filaments (from 3 to 20). In this way a rather sturdy yarn is obtained for the next working phases.

It should be considered that the single silk strand is extremely fine

Natural silk is ivory colored. It is whitened or colored by soaking it for several hours in stainless steel bins containing warm liquid in the desired color.

At this point the silk yarn is ready for weaving which is an extremely complex process.

Natural silk is ivory colored. It is whitened or colored by soaking it for several hours in stainless steel bins containing warm liquid in the desired color.

At this point the silk yarn is ready for weaving which is an extremely complex process.

There are two main types of weaving for silk, "heddle", a plain weave which is normally used to weave all other fabrics and "jacquard" weave.

There are two main types of weaving for silk, "heddle", a plain weave which is normally used to weave all other fabrics and "jacquard" weave.

This is done by laying out ink colors in successive stages (up to 20-25) and using the proper clichˇs thus creating exceptionally rich and varying patterns.

The "moirè" process involves a very light and delicate moving of some weft threads by means of perfect stainless steel cylinders. The threads which have been moved reflect light in a different way from the others with surprising optic effects. The fabrics obtained in this way are called "moirè".

This is done by laying out ink colors in successive stages (up to 20-25) and using the proper clichˇs thus creating exceptionally rich and varying patterns.

The "moirè" process involves a very light and delicate moving of some weft threads by means of perfect stainless steel cylinders. The threads which have been moved reflect light in a different way from the others with surprising optic effects. The fabrics obtained in this way are called "moirè".

Ties are produced either with jacquard or printed fabrics applied on plain cloth and the most luxurious are on jacquard fabrics which already have a rich background pattern. (see Tie-manufacturing)

Ties are produced either with jacquard or printed fabrics applied on plain cloth and the most luxurious are on jacquard fabrics which already have a rich background pattern. (see Tie-manufacturing)